Optimum design

Optimum design: the Bauhaus principle in the accelerator ring

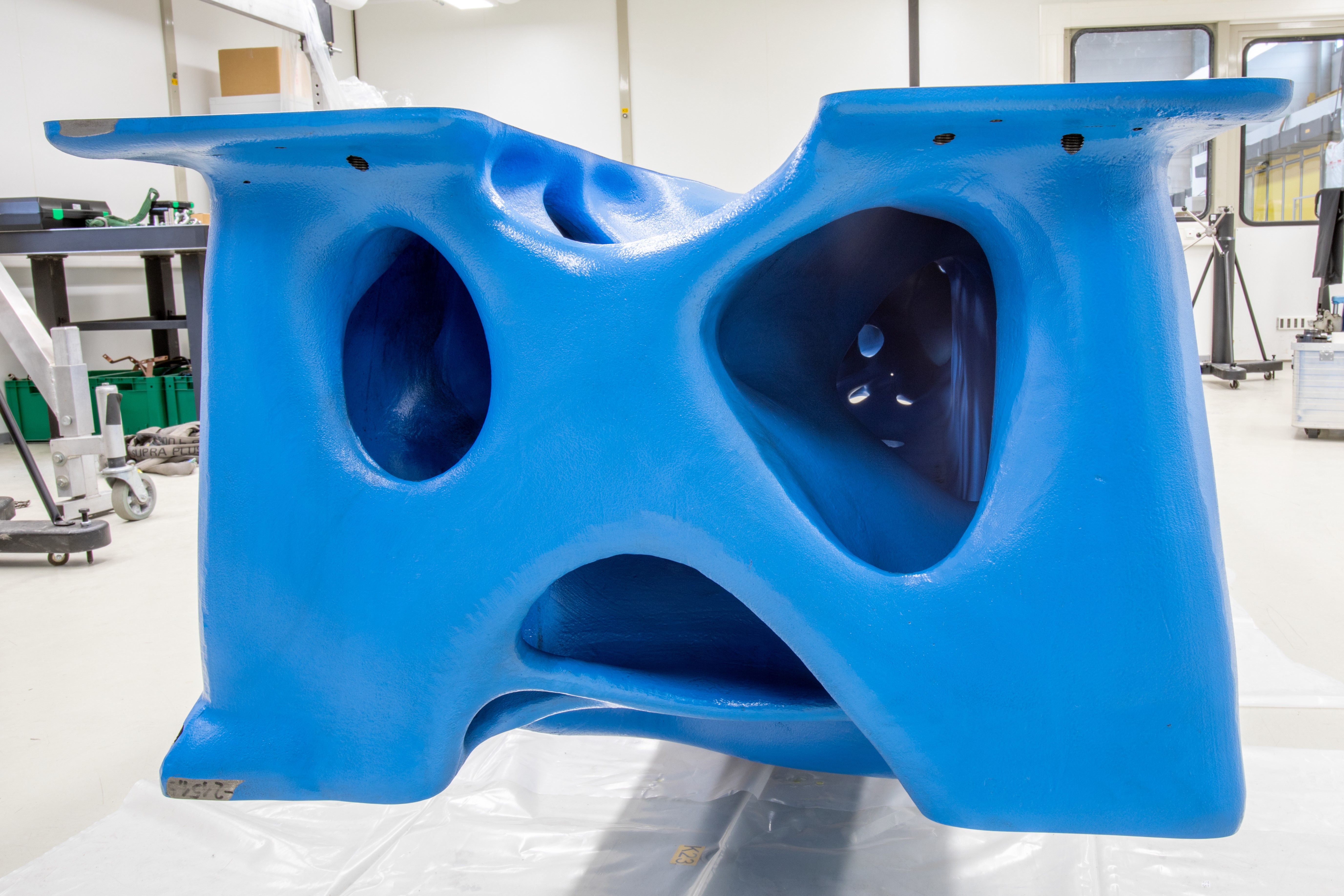

“Form follows function” – this principle of the Bauhaus school of architecture in Dessau is also applied at DESY. In building PETRA IV, the engineers are using cast metal supporting frames for the first time. Their design was first optimised using algorithmic models. The advantage of this construction method is that the supporting frames can be made lighter and still be stable – while also using less material.

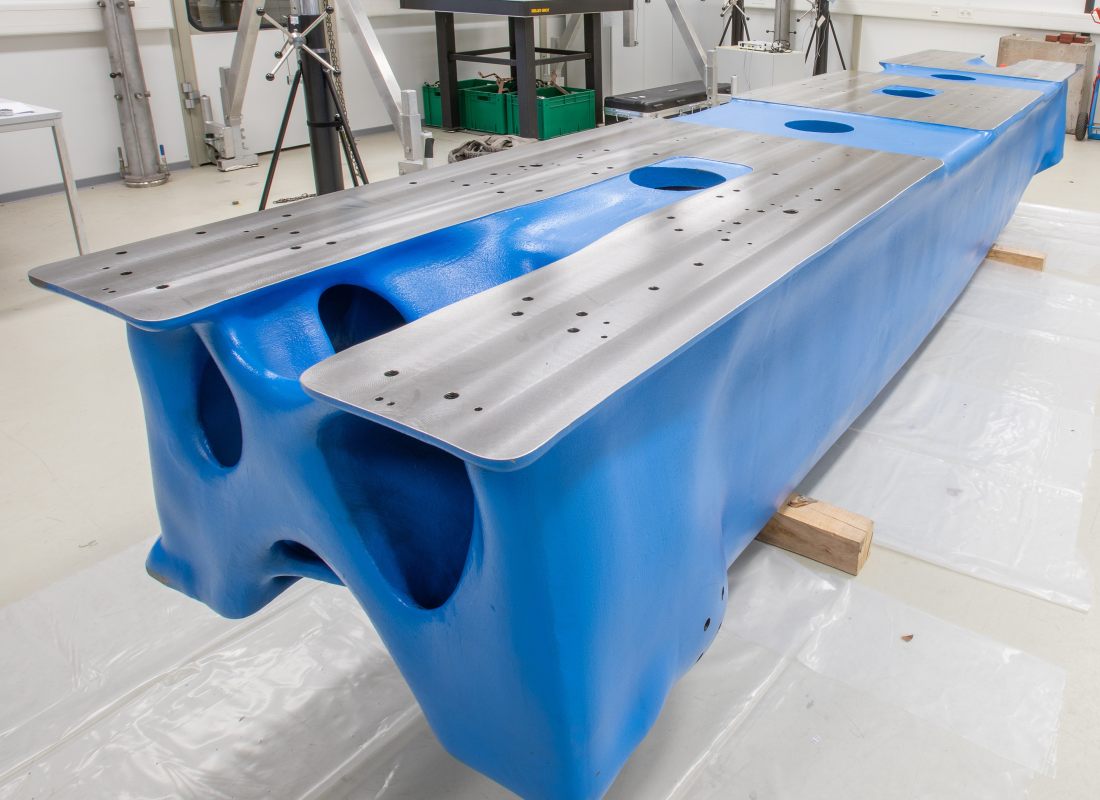

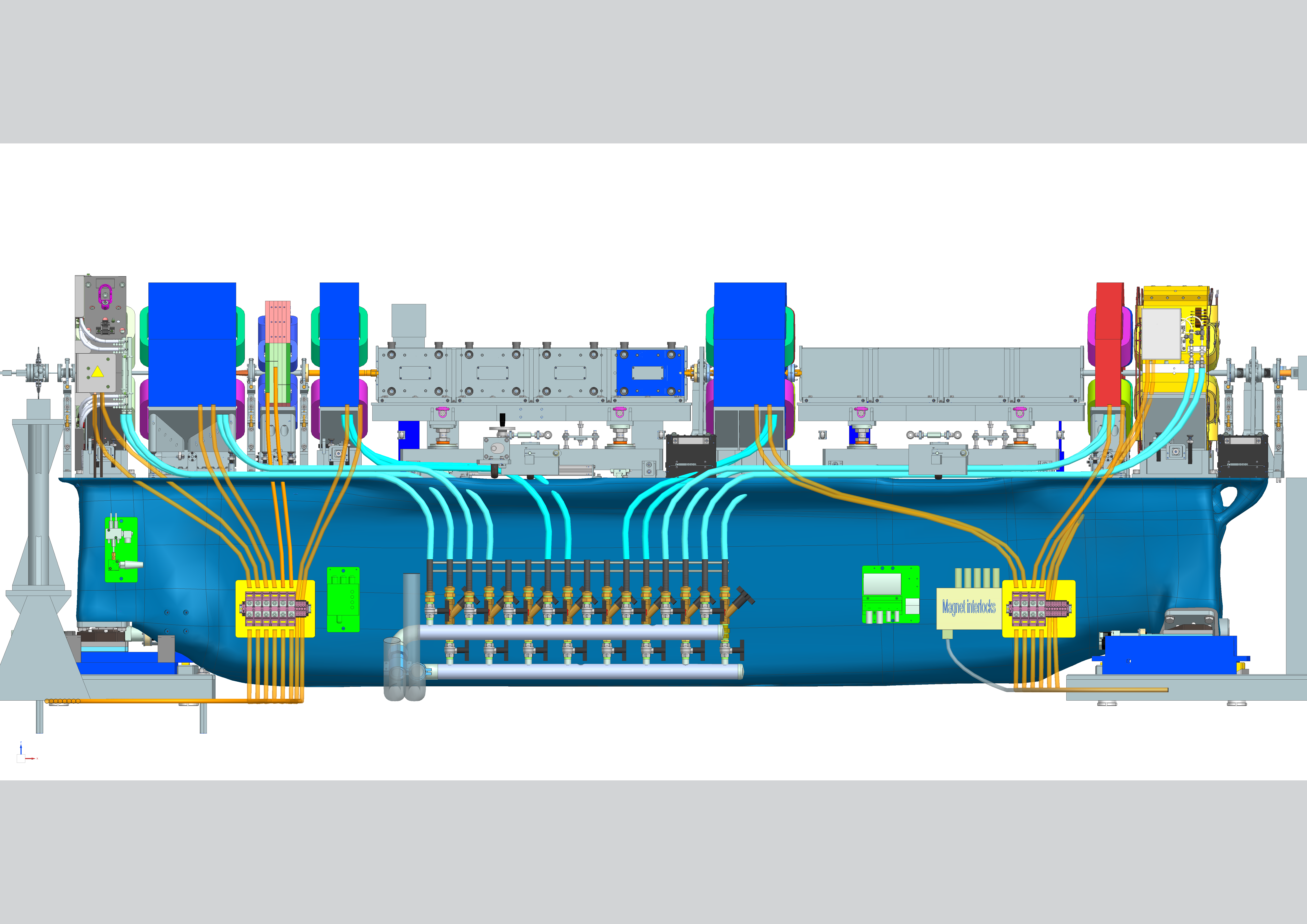

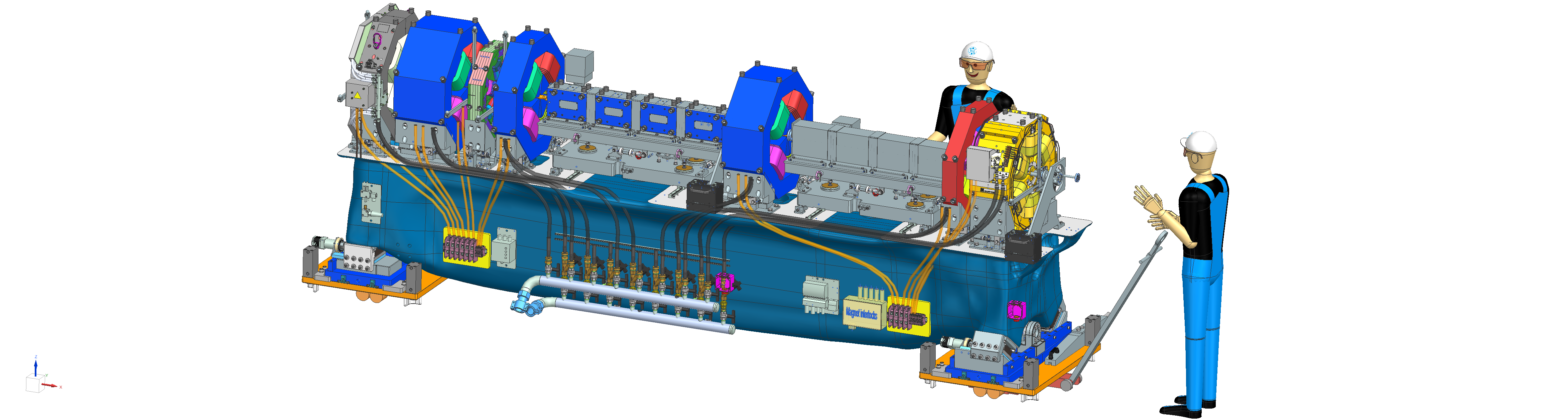

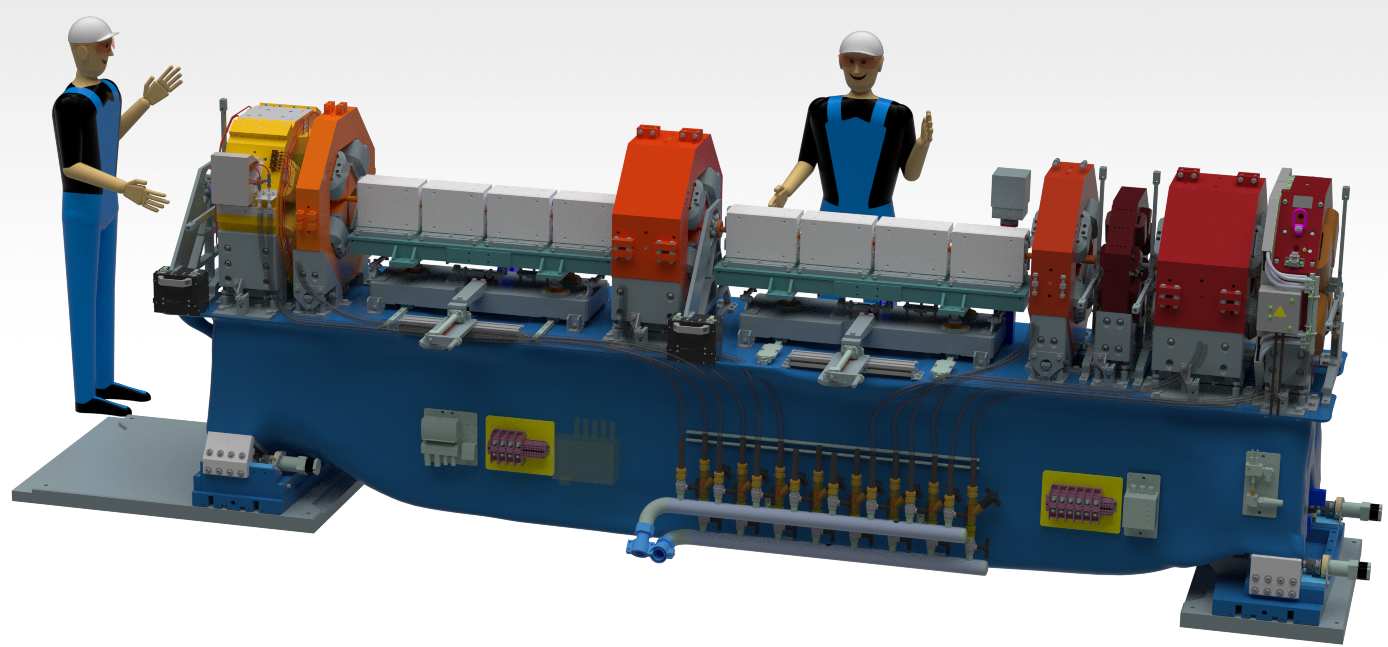

The experts at DESY are the first in the world to use an innovative skeletal construction technique to cast the metal for the supporting frames for PETRA IV. These frames, or girders, are about four and a half metres long and one metre wide and support the magnets that keep the particle beam precisely on track as it travels round the accelerator ring. In doing so, the beam in the 2300-metre-long ring must not be allowed to drift by more than 50 nanometres – one thousandth of the diameter of a human hair. This is equivalent to demanding that a car travelling from Hamburg to Munich, a distance of about 600 kilometres, should only deviate from its path by 13 millimetres – roughly the width of a fingernail.

“Conventional girders can no longer meet the enormous demands of the PETRA accelerators in terms of precision.”

Koldrack: “The problem is the vibrations. People dancing rhythmically in the nearby Volkspark Stadium, and even waves on the distant sea, can cause minimal vibrations in the girder.”

Preventing resonance

The problem arises when the frequency of an external disturbance coincides with the natural frequency of the girder. This results in resonance which amplifies the vibrations and compromises precision. Avoiding such vibrations is particularly important in ring-shaped X-ray sources.

An example illustrates the effect: When the string of a guitar is excited at its natural frequency, it begins to vibrate vigorously and produces a clear sound. Similarly, if external vibrations coincide with the natural frequency of the metal girder, it can begin to resonate. To prevent this, the girders are designed to resist external disturbances effectively by not absorbing their frequencies.

Sustainability meets precision

Normann Koldrack relies on a special computer-assisted procedure to design the new PETRA IV girders: topology optimisation. This uses algorithmic models to place the material exactly where it will be mechanically most efficient. An initial demonstrator was enhanced with bionic details, such as finely branching structures inspired by nature, which combine stability and lightness. The bionic elements were ultimately omitted from the final design without compromising its mechanical properties. “Topology optimisation has resulted in a particularly efficient design that also meets the vibration criteria,” says Koldrack.

Design for reducing material

The Coswig foundry in Saxony proved to be the ideal partner for the precise realisation of the special mould.A major advantage of casting metals is the amount of material this saves. The girders require at least 15 percent less material than similar structures, for example at the ESRF synchrotron in Grenoble. In addition, the metal used for casting can be 100 percent recycled, significantly reducing the carbon footprint. Although high-strength cast iron is somewhat less rigid than welded steel, the clever design actually surpasses it. The first prototype has already been completed and is undergoing testing.

Koldrack is confident: “We have met the criteria for stability and sustainability. There’s nothing to stop the series production of the 288 girders for PETRA IV from going ahead.”