New materials

The insights provided by PETRA IV at the level of individual atoms will allow new, resource-efficient products to be designed, including functional battery materials for electromobility, lightweight components for vehicle construction or organic solar cells made of cellulose.

Using friction experiments at PETRA IV, researchers can analyse how fine dust particles are released from a car tyre in contact with the road surface and how they disperse into the environment. Innovative materials could reduce the emission of nanoparticles from this abrasion in the future and thus lessen the potential danger from fine dust.

The finest abrasion, which is inhaled and enters the body as fine dust, is harmful to health. But abrasion causes even more damage: In industry, machines wear out due to abrasion, resulting in high maintenance costs. For the sake of people and the environment, researchers worldwide are therefore developing high-tech materials that are better protected against wear. To study these in detail, PETRA IV will provide sharp images of the friction process.

The high image contrast will make the abrasion visible during its formation. This is not possible with conventional imaging.

The imaging techniques made available by PETRA IV will allow researchers to study how batteries function while charging and discharging, from the millimetre range down to the nanoscale.

The planned highly standardised high-throughput beamlines will make efficient contributions towards developing new, sustainable types of batteries and bringing them to market. It will be possible to investigate many different variants of batteries simultaneously.

Ultrastrong X-rays with high energies

- The X-rays penetrate deep into the materials and capture them in 3D. Nanostructures will be observable over time – with simultaneously very high spatial resolution.

- The ultrastrong X-ray beam will allow the combination of different measurement techniques to decode relationships between the structure and electronic properties of materials.

- Only PETRA IV will provide the necessary high intensity at high X-ray energies. This will make it possible, for example, to measure the state of light elements such as lithium inside batteries.

Sustainable material as an alternative in vehicle construction

In the future, PETRA IV will significantly advance the production of new materials. Experts expect great progress, especially for the series production of 3D-manufactured components. These additive production processes are becoming increasingly important for aircraft and automotive construction, as they enable particularly lightweight materials with complex structures. Thanks to the mostly low material input, they are particularly efficient and energy-saving in production.

Paper layers as solar cells

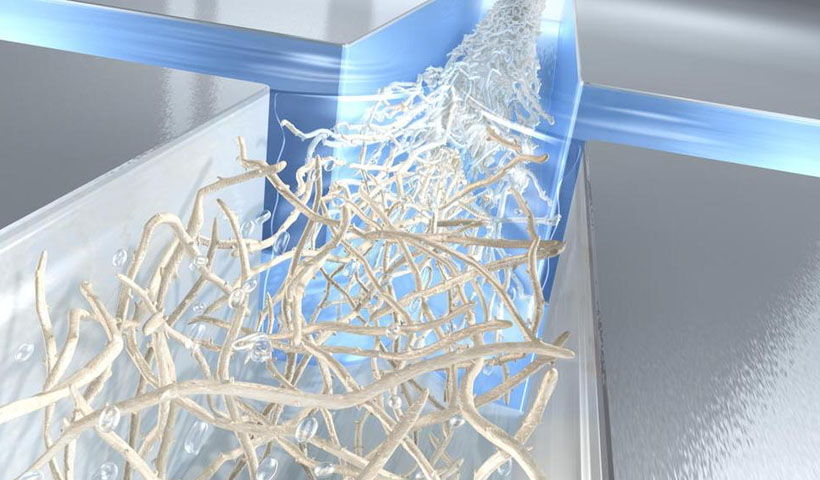

Not only in vehicle construction – such customised materials can also be important building blocks of the energy transition or in environmental protection. Findings from research with X-rays help to develop biodegradable substitutes – for example, artificial, high-strength cellulose fibres.

Heidrun Hillen

I am happy to answer your questions about PETRA IV.

Further research topics

Healthcare

How can diseases be better tackled?

Energy

How can we make more resilient materials?

New technologies

What do we need for the digital world of tomorrow?

Earth and the environment

How do we preserve our ecosystems?

Cultural heritage

How can we preserve our cultural treasures?