Sprayed-on solar cells

Organic solar cells are light, flexible and can be produced inexpensively. PETRA IV could help scientists to develop such components.

Conventional solar panels are made of silicon. But other varieties also exist: solar cells made of plastic, so-called organic solar cells. These are light and flexible and can be produced inexpensively using inkjet printers or deposition techniques. Until now, however, they have primarily been made from petroleum, and manufacturing them involves environmentally harmful solvents. PETRA IV could help scientists to develop significantly more sustainable organic solar cells.

To manufacture such a cell, different layers are deposited on top of each other to form a film, which then turns sunlight into electricity. Some of these layers contain polymers that are dissolved in a solvent. When the latter evaporates, the polymers are left behind as a solid layer. “Up to now, the chemicals used as solvents have contained chlorine,” says DESY physicist Stephan Roth. “But we are working on substances that are not so harmful to the environment.”

“The high-intensity X-ray beam from PETRA IV will allow the process to be monitored in much greater detail, because we would be able to measure it a hundred times faster than before.”

The team has already achieved some first successes, but PETRA IV is likely to accelerate the further development considerably. The solvents dry so quickly that the process can only be followed relatively imprecisely using today’s techniques. “The high-intensity X-ray beam from PETRA IV will allow the process to be monitored in much greater detail, because we would be able to measure it a hundred times faster than before,” explains Roth. “That way, we could gain a better understanding of the drying process.”

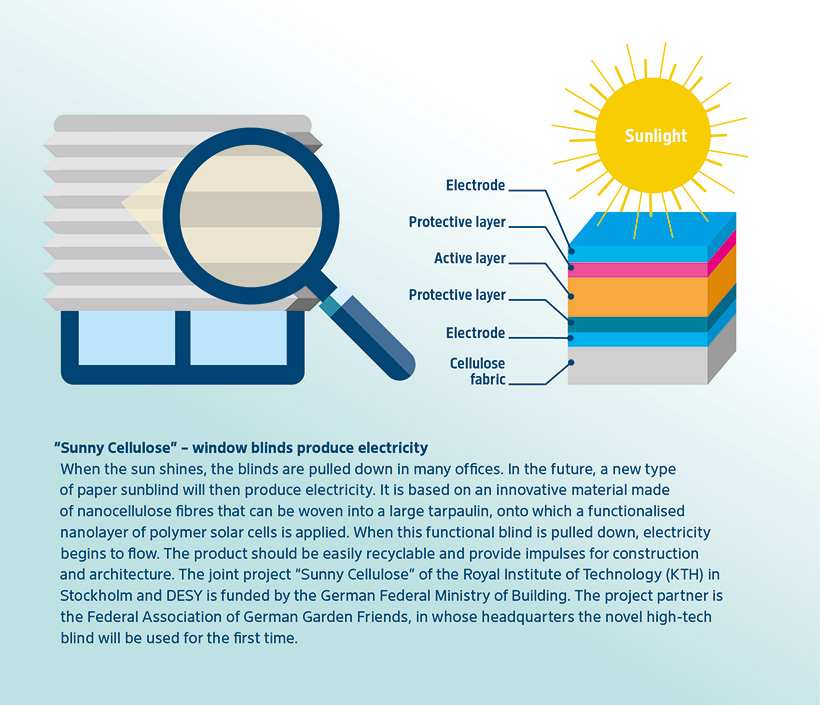

Another goal the scientists are pursuing is to replace the carrier material on which the polymers that generate the electrical power are deposited by a more sustainable material.

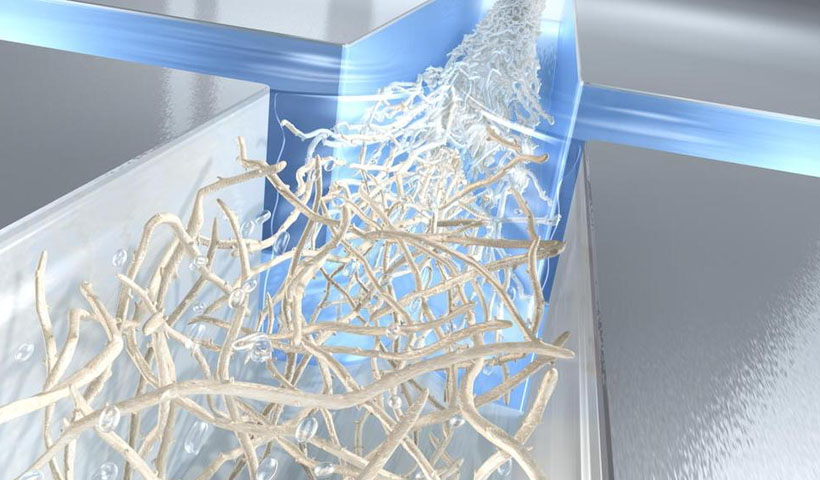

So far, plastic films have been used, for example, but in the future these could be made of an innovative wood-based material called nanocellulose. This is manufactured by first extracting filaments from wood; these are micrometres long and only five nanometres thick. The filaments can then be turned into a kind of nanopaper, which is a promising candidate for a sustainable substrate for organic solar cells.

“The extremely fine X-rays from PETRA IV will enable us to observe for the first time exactly how these nanofibrils and fibres form,” explains Roth. “This would allow us to produce nanocellulose much more systematically in the future and to customise its properties.”

The team has already achieved some first successes, but PETRA IV is likely to accelerate the further development considerably. The solvents dry so quickly that the process can only be followed relatively imprecisely using today’s techniques. “The high-intensity X-ray beam from PETRA IV will allow the process to be monitored in much greater detail, because we would be able to measure it a hundred times faster than before,” explains Roth. “That way, we could gain a better understanding of the drying process.”

Another goal the scientists are pursuing is to replace the carrier material on which the polymers that generate the electrical power are deposited by a more sustainable material.

So far, plastic films have been used, for example, but in the future these could be made of an innovative wood-based material called nanocellulose. This is manufactured by first extracting filaments from wood; these are micrometres long and only five nanometres thick. The filaments can then be turned into a kind of nanopaper, which is a promising candidate for a sustainable substrate for organic solar cells.

“The extremely fine X-rays from PETRA IV will enable us to observe for the first time exactly how these nanofibrils and fibres form,” explains Roth. “This would allow us to produce nanocellulose much more systematically in the future and to customise its properties.”

Heidrun Hillen

I am happy to answer your questions about PETRA IV.

Further research topics

Healthcare

How can diseases be better tackled?

New materials

How can we save resources?

Energy

How can we make more resilient materials?

New technologies

What do we need for the digital world of tomorrow?

Earth and the environment

How do we preserve our ecosystems?

Cultural heritage

How can we preserve our cultural treasures?