Detailed images of implants

Magnesium screws have advantageous properties: The elasticity of the material is similar to that of bone, but it dissolves gradually inside the human body. This process of dissolution is being closely examined at PETRA’s beamlines.

Screws made of magnesium, which are implanted to fix broken bones, are claimed to have a big advantage over today’s implants made of stainless steel or titanium: They dissolve over time. Once the bone has healed, they no longer need to be removed in a physically stressful follow-up operation. Stents – mesh-like vascular supports for cardiac vessels – could also be based on magnesium in the future, allowing them to dissolve inside the body once the tissue has stabilised. PETRA IV will significantly advance the further development of this medical technology of the future.

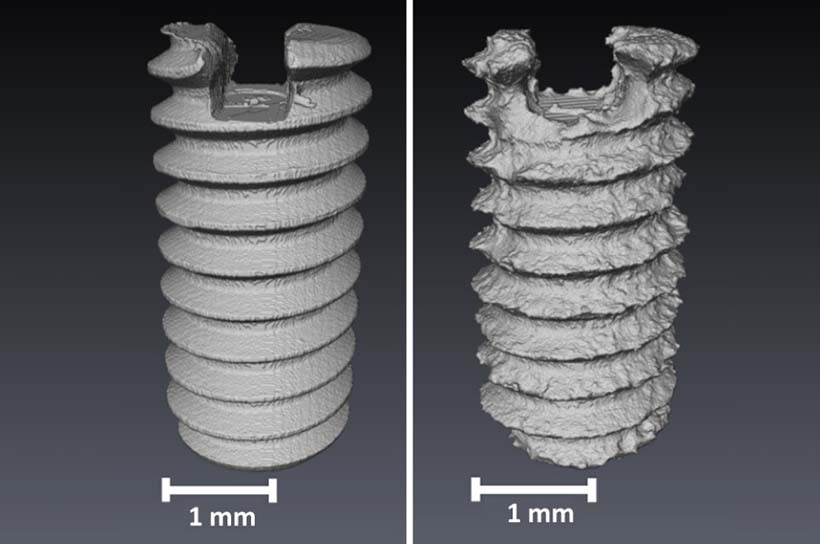

One of the main research challenges is finding suitable magnesium alloys: If they decompose too quickly, they may not stabilise the bone for long enough. If they dissolve too slowly, it may become necessary to operate again after all. That is why experts are testing different alloys in a series of long-term tests. An important analytical tool in this process is microtomography. This is similar to a CT scanner in a hospital, which produces 3D X-ray images of the inside of the body. However, instead of illuminating the samples using conventional X-ray sources, the intense X-rays from PETRA III are used. In combination with other X-ray methods, this allows a detailed analysis of how the implants gradually decompose and how the bone reacts to this.

PETRA IV is going to expand this spectrum: In particular, the new facility will give momentum to another technique, known as phase contrast imaging. “This allows soft tissue, which is fairly indistinct in conventional images, to be recorded in much greater detail,” says Felix Beckmann, a scientist at the Helmholtz Centre Hereon, which maintains an outstation at DESY.

“Thanks to its significantly better beam properties, PETRA IV will be better suited for this than PETRA III is today.”

This would have a number of advantages for the future development of biodegradable implants: “Among other things, cartilage formation could be analysed in much more detail than before,” says Beckmann’s colleague Berit Zeller-Plumhoff. “This precedes the formation of bone and marks an important stage in the healing process.”

Research into dissolvable stents would also benefit: At the moment, the blood vessels into which a stent is inserted can only be seen relatively poorly in the images. PETRA IV’s intense X-ray beam could, by contrast, reveal the detailed structure of the vessel – and how it reacts to the implant.

Heidrun Hillen

I am happy to answer your questions about PETRA IV.

Further research topics

Healthcare

How can diseases be better tackled?

New materials

How can we save resources?

Energy

How can we make more resilient materials?

New technologies

What do we need for the digital world of tomorrow?

Earth and the environment

How do we preserve our ecosystems?

Cultural heritage

How can we preserve our cultural treasures?