An alternative to plastic

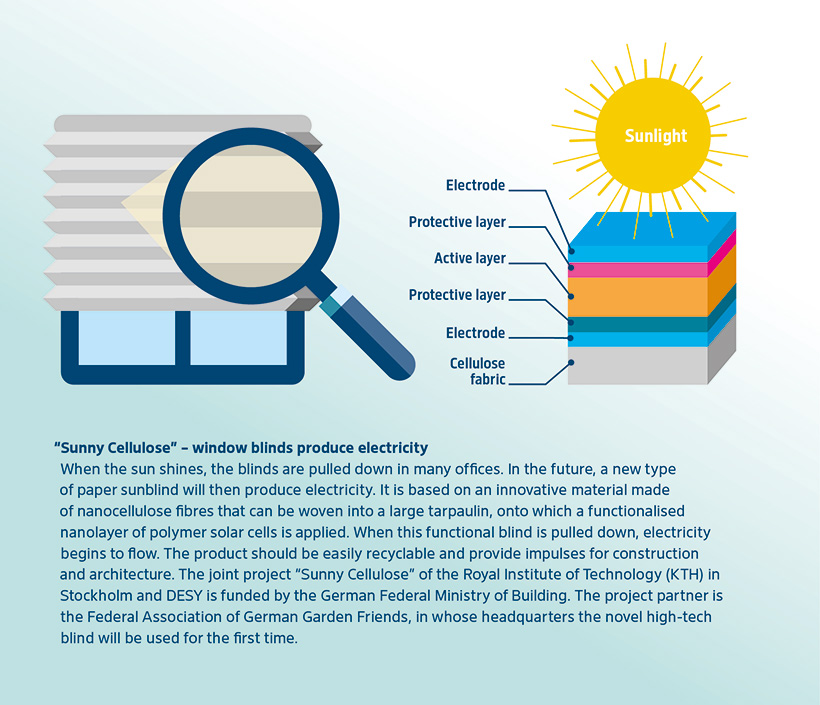

A solar blind acting as a solar module – sustainably produced and made from natural materials.

A new kind of material is being created from natural raw materials such as wood: nanocellulose. The material is more robust than any other known biomaterial in the world – stronger than steel and with a tensile strength like spider silk. The cellulose threads can also be used to make a special nanopaper, which is to serve as a carrier material for organic solar cells.

“The high-intensity X-ray beam from PETRA IV will allow the process to be monitored in much greater detail, because we would be able to measure it a hundred times faster than before.”

“We simply spray the polymer solutions onto the nanopaper with a nozzle,” explains DESY scientist Stephan Roth. “This has several advantages over the usual method – printing.” For example, spraying is extraordinarily fast and the liquid can be applied to objects of any shape, such as a corrugated roof tile.

In a test setup at PETRA III, this spraying method works quite reliably. The system carries out the various production steps automatically, and at the same time, the high-intensity X-ray beam can be used to observe in detail how the polymers are deposited and aligned in the cellulose carrier.

The team now aims to produce not only the carrier material from nanocellulose, but also other layers that are necessary for the solar cell to function, especially the electrodes. These electrodes must be able to conduct electricity as well as possible – a property that nanocellulose does not possess. The researchers therefore incorporate tiny metal particles, so-called nanowires, into the cellulose mesh – turning the insulating nanopaper into a conductive electrode.

“The principle works,” says Roth. Soon, in cooperation with a company, the technology will be integrated into a building and tested under practical conditions.

There are still various hurdles:

- Water resistance: Natural materials could perhaps be used here (waxes, tree resins)

- Durability of the cells

- Stability of the thin cellulose carriers

“We believe that these cells can be produced cheaply,” says Stephan Roth. “And, in principle, it should be possible to recycle them quite easily after use.” Instead of being hazardous waste, the solar cells made of cellulose could then end up on the compost heap or in the waste paper bin.

Heidrun Hillen

I am happy to answer your questions about PETRA IV.